The CHARM project had a challenging start during the COVID-19 pandemic, without face-to-face meetings. However, cooperation has worked well between work package leaders and good communication and working practices are now in place. Find out here how each of the six use cases has progressed so far.

The project coordinator, Valmet Oy, has focused on establishing working practices with the project handbook, review of identified risks and plans and practices for innovation management, communication and dissemination. Project focus has been on requirements, specifications and system architecture for the six use cases, with all partners involved. In parallel, the requirements and specifications for the materials, sensors and components have been created and development work and reliability testing has come to a good start. All planned project deliverables and the two first milestones have been achieved during the first project year.

Image 1: Prototype radar sensor mounted on a test vehicle.

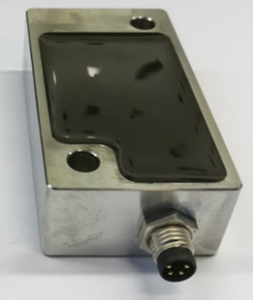

Image 2: Protected position sensing electronics and calibration of measurement for inside a roll monitoring.

Image 3: Illustration of harsh environment in the machining area during operation.

Image 4: Oven for solar panel manufacturing.

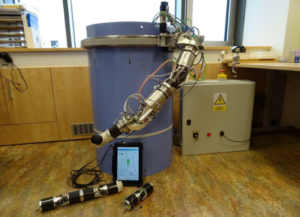

Image 5: Prototype of in-service inspection robotic arm for nuclear power plant maintenance.

Image 6: Illustration of some of the challenges in industrial printers: Ink droplet positioning, ink smearing and paper wrinkling.

Partner innovations have come to a good start, even though the project focus has been on requirements and specifications. There are already new ideas and innovations from several partners, with IPR protection activities and FTO (freedom to operate) studies ongoing.